Anritsu will be showing advanced solutions supporting the latest 5G standards and network deployments at Mobile World Congress (MWC) 2023 at Barcelona (Hall 5 Stand D41). As a long-term partner in the Telecom Industry for test and analytics solutions, Anritsu is developing innovative new solutions to help accelerate the transformation of new products and services for 5G Industry Verticals.

Anritsu’s stand will demonstrate how its solutions underpin new use cases such as Smart Factories and Autonomous Driving, the metaverse and digital twins, while also providing thought leadership and opportunities to learn about emerging technologies.

Technologies and Measurements for Beyond 5G

3GPP has started work on ‘5G-Advanced’ from Release 18, and industry and academia are already evaluating technologies for 6G. Anritsu is participating in multiple projects and consortia to help define and shape future telecoms technologies and related measurement requirements.

Metaverse user experience over 5G with real world mobility in partnership with InterDigital

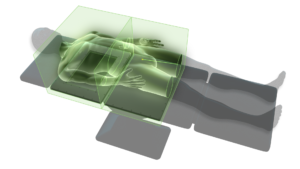

Interruption of data during mobility can disrupt immersive user experience applications that rely on low latency network services. 5G New Radio (NR) introduces significant improvements in latency and data interruption, but further improvements can be made by changing radio network and user equipment. Anritsu will showcase the simulation of real network conditions in an ultra-flexible test lab environment, demonstrating smarter 5G UE and network behaviours and a use case that embodies the metaverse’s challenges of uplink bandwidth, latency, and synchronisation.

Test Solution for 5G Enabled Automated Valet Parking in partnership with dSPACE

Anritsu and dSPACE GmbH have developed a test and simulation environment for Automated Valet Parking (AVP).

Based on AVP Type 2, we will show how 5G can be used to send the parking request to the AVP service. The vehicle will then be dropped off by the driver and automatically driven by the AVP system to its intended parking spot. When requested by the vehicle’s owner, it will be retrieved automatically.

This solution features Anritsu MT8000A Radio Communication Test Station and dSPACE VEOS (a PC-based simulation platform), with dSPACE AURELION sensor-realistic simulation providing a 5G network slicing testing environment for Automotive V2X Use Cases.

RIS Measurements with PhaseLync Technology in partnership with Greenerwave

Reconfigurable Intelligent Surfaces (RIS) is an electronic device, composed of many layers with a surface inlaid with a set of patch antennas, called pixels (or unit cells) whose electromagnetic (EM) response could be controlled via a control board. It is proposed in the framework of 5G and Beyond connectivity to steer radio signals between a transmitter and receiver, giving better reception or link quality.

Greenerwave, a French SME founded in 2016, has built the first RIS worldwide using off-the-shelf electronics and PIN diodes. Its know-how in electronically steerable antennas has been widely recognised in many business applications.

However, measuring the magnitude and phase characteristics of high frequency RISs at various distances and conditions is challenging, as no Vector Network Analyzer (VNA) can separate the two ports of the VNA over longer distances. Anritsu’s PhaseLync technology distributed VNA system ME7868A can make these measurements over 100 meters, characterising a RIS surface performance in a real environment.

This partnership between Anritsu and Greenerwave on a challenging problem will open the door for RIS technical specifications in several environments that allows to benchmark the technology against existing solutions.

O-RAN Test Solution for O-RU

Open RAN is driving flexibility and intelligence in mobile network using multi-vendor disaggregated products. The key challenge is to reduce the complexity of testing and to maintain network performance.

Anritsu contributes to build secure mobile network by providing a unique solution for O-RU (O-RAN Radio Unit) testing. The solution improves the test efficiency via test automation and the quality of O-RU by offering test scenarios closer to real network situation.

Field Test – Network Latency Measurements for UR/LLC

High value services on 5G and future 6G mobile networks will require very low latency. Ultra-Reliable Low Latency Communication (URLLC) is key for applications such as autonomous vehicles, medical, Multiple Access Edge Computing (MEC), and Metaverse technology.

Mobile network operators need to ensure low latency across their network, combined with network synchronisation, ensuring support for critical services.

Anritsu MT1000A Network Master Pro, a portable easy to use test solution with 10GE, 25GE and 100GE interfaces, helps simulate mobile car connectivity. This allows accurate analysis and mapping of the distribution of latency values, throughput, and jitter values and ensures required network performance for URLLC and end-to-end quality of service. Anritsu will demonstrate the MT1000A test setup, showing a live demo of a real network latency measurements and data mapping.

Complete toolbox for 5G base station field engineers

Anritsu’s Field Master Spectrum Analyzer family offers best-in-class performance for current and future testing needs in a wide range of commercial, private, and government use cases.

Field Master MS2080A, the latest addition to the Field Master Family, integrates all the tools required to install and maintain the radio performance of standalone and non-standalone 5G networks. Field technicians have everything they need in one package – spectrum analysis, 5G and LTE transmitter measurements and cable and antenna line sweep measurements.

Additional tools for spectrum clearing and interference hunting will also be demonstrated at Mobile World Congress.

For regulators validating compliance with national standards and network operators testing the performance of new base stations, MS2080A provides all the measurements needed in a portable light weight instrument with time saving automatic report generation.

Anritsu Service Assurance – Beyond Automated Assurance

Assurance of telecoms networks is moving away from troubleshooting and assessing subscriber and network experience to become an integral part of how future networks must work. Autonomous networks using advanced automation require real-time subscriber-level insights, machine learning, and automation.

Anritsu Service Assurance gives operators real-time insight into subscribers’ experiences, allowing them to fix network issues without delay. As a result, operations teams run more efficiently and with complete visibility across all technologies and services.

For 5G Private Networks for large enterprises, assurance systems allow in-depth insights into device experience or mobility.

Visit the Anritsu Service Assurance stand at MWC to learn about the journey to the autonomous telecom cloud, including demos on automation, anomaly detection, and private networks.

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control