What factors should you consider if your business is operating at full capacity and you contemplate outsourcing work to a contract electronics manufacturer? Steve Marshall, managing director of Offshore Electronics, has the answer.

Financial constraints can make it difficult – if not impossible – to grow a business when, say, you are working flat out and you win a new contract, or a urgent job suddenly comes in. As well as the cost of materials, investments also have to be made in factory space, machinery, and extra staff.

However, additional manpower, machinery and production capacity can be prohibitively expensive. Besides, it will take considerable time to train up the right people in the specific skills you will require to complete the job.

This is where contract electronics manufacturer (CEM) can make all the difference because working with a CEM allows flexible expansion without major investment. It also lets the recipient respond to unexpected or unplanned demands quickly, and without the need for extra training and development. Furthermore, outsourcing manufacturing capacity allows companies to focus on their core business while having secondary processes taken care of by outside experts.

CEMs are companies that make products under contract for other companies. They typically take on manufacturing responsibility for original equipment manufacturers (OEMs), either wholly or partially. Simply put, CEM involves the OEM giving away some business tasks that can easily be managed by an independent entity, making life less expensive and more productive for your business.

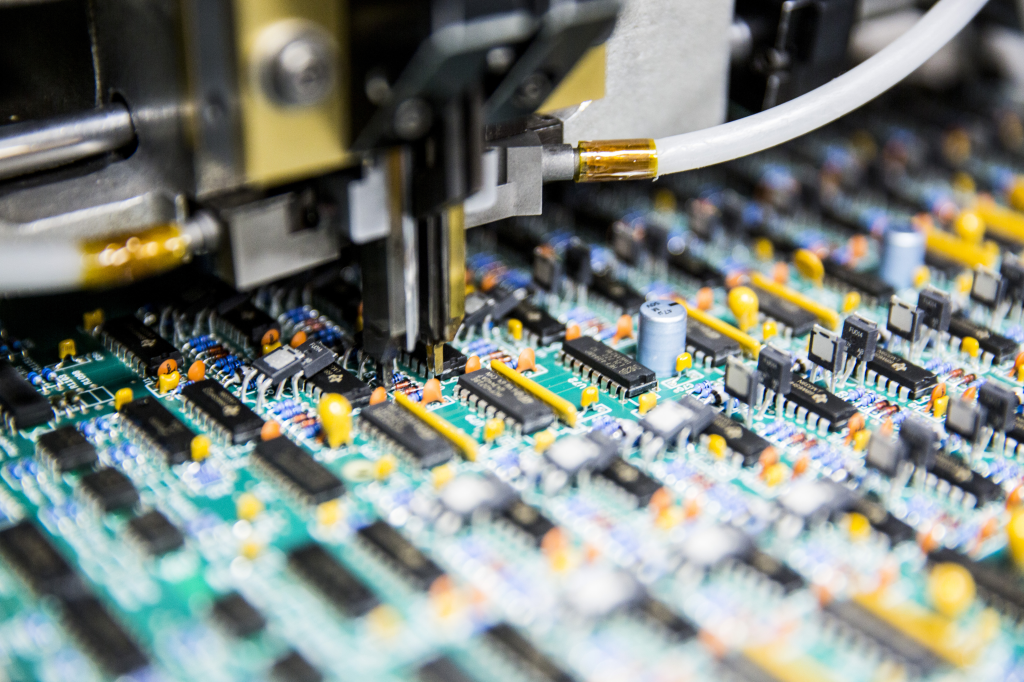

After all, electronics manufacturing – and the plant and equipment needed to achieve it – tends to work on a large scale. A company buying, for example, a surface mount machine, would be unlikely to use its full capacity. A far better idea is to sub-contract out that portion of work to a CEM that has the capacity and economy of scale to make the investment viable.

Offshore Electronics, for example, can provide complete, cost-effective contract electronics engineering solutions for any challenging manufacturing requirements. It offers a complete service from design for manufacture to prototypes, through to electronics and electro-mechanical production and assembly, test and quality control, to customised packaging and delivery.

The company works in the fields of industrial and scientific machinery – such as industrial controllers and medical equipment. The products that it manufacture are generally highly complex ones that require testing.

However, a good CEM does more than simply ‘follow orders’. For example, when presented with printed circuit board layouts that are over-engineered, expensive and difficult to produce a good CEM will offer a prototyping service that helps designers remove complexity and cost from a project. Offshore Electronics have helped many customers to redesign a product so that it is cost efficient to manufacture. As well as minimising costs, this can also accelerate manufacturing and improve product reliability.

CEMs are often seen as the exclusive preserve of global players and multi-nationals, but this is a false perception. In fact, many companies, including my own, work closely with small and medium enterprises (SMEs) to help them get their products to market. Indeed, SMEs are often more likely to benefit from the services of a CEM.

For example, an SME may be too small to handle ISO accreditations, or meet European Union compliance rules (despite Brexit, these will still be required in order to sell products into the EU). Repeatability, reliability and product quality can also be tough to achieve without the backing of a CEM which can offer everything from buying components, assembling the products, testing and shipping the final product.

Of course, it can be hard to let go of any aspect of a business. Control is important and, for a company that is self-sufficient and has intimate knowledge of its products, the notion of handing all this over to somebody else can be daunting. Yet it makes sense in so many ways.

First, there is the use of resources. An electronics start-up will typically have the majority of its expertise in design and the market they operate in. The value of the company lies in its skilled staff and the Intellectual Property, or IP (the intangible property that is the result of creativity, such as patents and copyrights) that they have helped to generate.

If anything, a good sub-contractor will enhance a company’s reputation, because it is focused purely on manufacturing: it will have the specialist staff and machinery, manufacturing capacity, buying power and – crucially – expertise in compliance to ensure that the final product is top class.

Of course, with valuable IP there is always the fear of patents being stolen. However, choosing a reputable sub-contracting partner who respects non-disclosure agreements should neutralise this fear.

Indeed, using a company like Offshore Electronics has an added layer of security because it is based in the highly regulated and trusted jurisdiction of Guernsey in the Channel Islands.

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control