From February 21 to 22, 2024, maintenance in Dortmund, Germany’s leading trade show for industrial maintenance, will offer its audience an insight into the entire spectrum of industrial maintenance under the main motto “Predictive Maintenance: Next Generation”. Schaeffler is showcasing its comprehensive range of products, services and solutions in the …

Read More »World’s most powerful wind bearing test facility: Schaeffler cooperates with LORC and R&D Test Systems

The expansion of renewable energies is being driven to a great extent by wind turbines. Wind turbines are becoming larger and more powerful. The main shaft bearing system, as an integral part of the drive train, is of elementary importance, as this is where all the forces and torques exerted …

Read More »A cool condition monitoring solution

Global automotive and industrial supplier Schaeffler has supplied a fruit processing company with its ProLink condition monitoring system to monitor the condition of trolley bearings on stacker cranes, which operate in cold and frozen storage areas. Zentis GmbH & Co. KG, with its headquarters in Aachen, Germany, is one of …

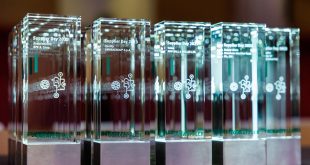

Read More »Schaeffler rewards suppliers for outstanding performance

The global automotive and industrial supplier Schaeffler presented 19 of its suppliers with the Schaeffler Supplier Award at the Supplier Day in Herzogenaurach, Germany, in honour of their exceptional performance. Georg F.W. Schaeffler, Family Shareholder and Chairman of the Supervisory Board of Schaeffler AG, and Klaus Rosenfeld, CEO of Schaeffler …

Read More »The OPTIME Ecosystem: Innovative condition monitoring and smart lubricant management in one solution

The global automotive and industrial supplier Schaeffler combines its OPTIME Condition Monitoring system with the sensor variants OPTIME 3, OPTIME 5, and OPTIME 5 Ex for wireless condition monitoring and its intelligent, interconnected lubricator OPTIME C1 for automated lubrication to form one solution: the OPTIME Ecosystem. This creates a cost-effective …

Read More »Acquisition of ECO-Adapt SAS strengthens Schaeffler’s portfolio of Lifetime Solutions

The global automotive and industrial supplier Schaeffler has announced the acquisition of 100 per cent of the shares in ECO-Adapt SAS. ECO-Adapt SAS offers innovative solutions for condition monitoring based on electrical signal analysis and systems for the optimisation of energy consumption. The acquisition expands the Industrial division’s portfolio of …

Read More »Schaeffler publishes 2022 Sustainability Report

Sustainability is an integral part of the company strategy and one of the four corporate values of the Schaeffler Group. The company accepts environmental and social responsibility along the entire value chain. In 2022, the Schaeffler sustainability strategy was aligned even more clearly with the three dimensions of Environment, Social …

Read More »Schaeffler securing green electricity from wind power

Automotive and industrial supplier Schaeffler will purchase electricity from wind turbines in the long term from Statkraft Markets GmbH, a leading international producer in the field of renewable energies. The plants, commissioned in October 2022 in Staufenberg, Hesse (Giessen district), will provide green electricity with a total capacity of around …

Read More »Climate targets validated by Science Based Targets initiative

The Science Based Targets initiative (SBTi) has validated the Schaeffler Group’s targets for reducing greenhouse gas emissions as being in conformity with SBTi criteria and recommendations and hence in line with what the latest climate science considers necessary in order to meet the goals of the Paris Agreement. The global …

Read More »PTC and Schaeffler announce new strategic alliance to accelerate digital transformation roadmap

PTC and Schaeffler have announced a new alliance that will see the global automotive and industrial supplier standardise PTC solutions to deploy an integrated, end-to-end IT landscape. Schaeffler, which has UK bases in Birmingham, Hereford and Sheffield, will also inform the internet of things specialist in its efforts to further …

Read More » Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control