By Aaron Merkin, Chief Technology Officer for Fluke Reliability

Organisations have been dealing with a myriad of uncertainties affecting their business operations over the past few years, but are finally starting to see some stability in their operating environment. While this stability is welcome, the key for most reliability and maintenance organisations as we head into the new year is resilience — having the strength and flexibility to weather the constant changes that have become the norm.

We see resilience taking many different forms in 2023, but the common trend seen in organisations is to use technologies to provide insights that improve operational reliability.

Resilience Powered By AI

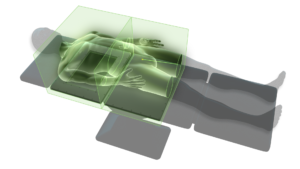

We are seeing an increased need for businesses to proactively monitor a broader set of assets in order to achieve their overall plant reliability objectives. Artificial intelligence (AI) and Machine Learning (ML) coupled with IIoT sensing technologies are one mechanism for organisations to expand their asset coverage. AI and ML systems are already processing huge amounts of data in real time, describing what’s going on, predicting asset faults, and even prescribing actions that need to be taken in order to solve issues at the earliest opportunity.

What we’re not seeing is AI totally replacing experts in the plant — evidence of what you might call the resilience of expertise. Whilst many predict fully automated processes in the future, we note that although AI may highlight an issue or condition that needs attention, ultimately there is still a human who is signing off on it before a work request is created. We expect to see more of this mixed model approach, where customers still employ the human expertise, but the experts can use AI to make themselves more efficient.

Cloud Adoption

Cloud adoption is not new — it has been a constant for many years — but it is an ongoing trend that is being utilised effectively by small and medium enterprises, especially those with multiple sites. As managers struggle to get IT support to deploy solutions, cloud technologies have been easier for them to implement in a facility without having to engage their IT department in a large-scale project. If you’re a maintenance engineer who has been tasked with improving the reliability of assets, deploying a cloud-based solution that doesn’t require IT support empowers you to solve the problem without having to coordinate with another team.

For operations with multiple plants and a breadth of employees working on separate operations toward the same end goal, cloud adoption is critical. Each team can collect and share data with their counterparts which in turn, breaks down operational / multi-site silos and therefore, informs decisions that positively impact asset lifecycles.

Supply Chain Resilience Remains Critical

Supply chain issues are still pervasive, but cloud-based solutions can be used to add resilience to future-proof against continued volatility in the marketplace. We are seeing improvements in supply chains as well as in parts availability, but still find that customers can’t necessarily get the spare parts as quickly as they need to, so they’re trying to make better use of their internal stores.

One benefit of a cloud solution is that you can easily aggregate information about multiple sites which allows organisations to have better visibility into parts and inventory. For example, rather than going back to a supplier for a part for plant A, you can go to plant B and take that stock.

Mapping out entire supply chains end –to-end to minimise exposure to risk helps mitigate uncertainty. For maintenance and reliability teams, inventory management solutions that offer data-driven insights will improve the overall efficacy of maintenance control.

Expert Constrained Companies Will Utilise Services to Close the Growing Skills Gap

Whether it be the great resignation or skilled talent retiring, it’s not news that the global skills shortage continues — call it the “new normal”. Talented people are moving around the industry or simply reassessing their work life balance and how their current business supports that.

In 2023, we expect companies to take greater advantage of in-built service offerings where experts can be on hand to advise full-time staff on maintenance and reliability programs to leap-frog the skills gap for permanent employees.

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control