A customer came to us with a requirement to measure the torque setting of air drivers being used on an assembly line. They had been experiencing fasteners being damaged and suspected that incorrect torque settings were causing the issue. Testing had to be carried out on the assembly line, which had multiple workstations. A portable, yet robust and accurate test solution was required.

A customer came to us with a requirement to measure the torque setting of air drivers being used on an assembly line. They had been experiencing fasteners being damaged and suspected that incorrect torque settings were causing the issue. Testing had to be carried out on the assembly line, which had multiple workstations. A portable, yet robust and accurate test solution was required.

The Solution

We were able to help with the USB version of our T15, Hex Drive rotary torque transducer.

The T15 is a contactless design torque transducer, capable of up to 2,500 samples per second at 4,000RPM to an enhanced accuracy class of 0.1% full scale. The USB version offers the additional advantages of being powered by the USB connection to a PC or laptop, so no external power is required.

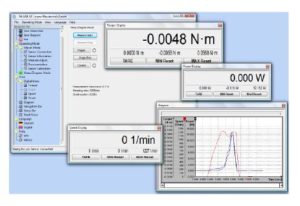

In addition, the T15-USB is supplied with our BluDAQ, Windows compatible data logging software, enabling view live data viewing and automatic data logging. Data can also be exported in BMP or CSV file formats for further analysis in other software packages.

The T15 torque transducer could be installed quickly and easily between the air driver and fittings on each workstation. This enabled data to be collected, viewed and saved in just a few moments. Any adjustments to incorrectly setup air drivers could be made and checked without a lengthy shutdown of the production line. Saving time and money

The Range

Interface Force Measurements offers a range of torque transducers with USB output. All with the same advantages of the T15.

The complete range consists of T12 – Square Drive; T15 – Hex Drive and T25 – Shaft style. All in capacities from 0.1 to 5,000Nm and capable of measuring at speeds up to 30,000RPM.

All these sensors are also available with analog, ±5vdc outputs.

BluDAQ Software

All our USB Torque Transducers are supplied with BluDAQ software from Interface Force Measurements, free of charge. BluDAQ is a fully-featured, Windows compatible data logging software package with

- Torque, speed, and power OR torque = angle

- Display, graph, and logging

- Up to 2,500 measurements per second

- 16-bit resolution

- Peak & valley

- Unit conversion

- Triggered start & stop for automatic event capture

- Automatic scaling of Y-Axis

- Log files are in Excel-compatible .csv format

- Power supply over USB – no separate power cord

- Configuration & calibration stored in the sensor

All these features make the interface USB range of torque transducers offer a simple and convenient method of accurately measuring torque without requiring external power or excitation. Data can be viewed live and recorded. Triggered start and stop for automatic data capture ensures no data is lost.

If you would like more information about our USB torque transducers or any other of our force, torque or pressure measurement sensors, please visit our website, interfaceforce.co.uk or contact us by calling 01344 776666 or by email at info@interface.uk.com

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control